This website uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognising you when you return to our site or helping our team understand which parts of the site you find most interesting and useful.

Product specifications

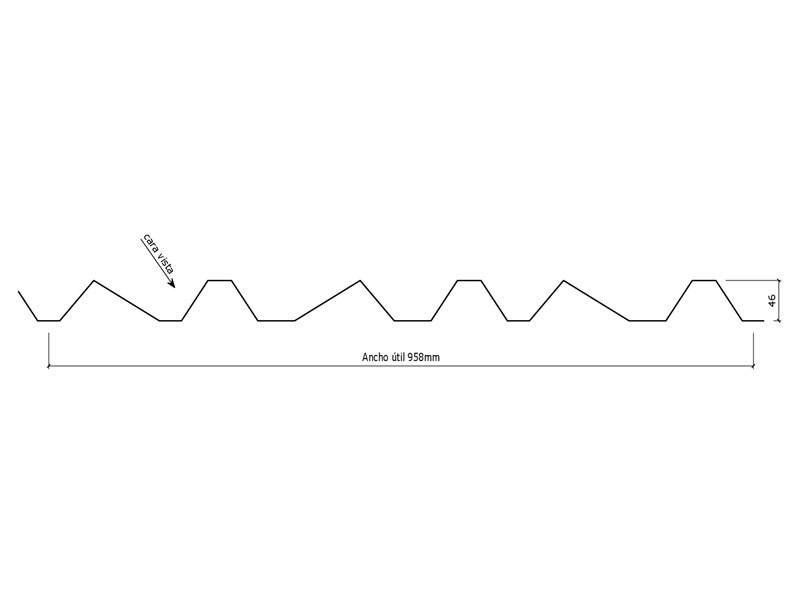

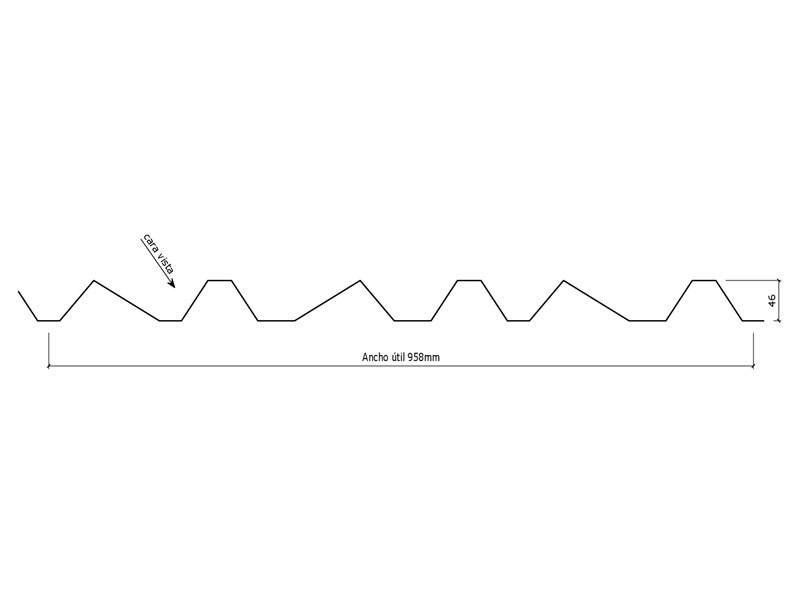

The cladding profile Cabrera belongs to the range of architectural profiles designed and manufactured by TAS. This profile offers a modernist appearance that is different from any other façade thanks to its asymmetrical geometry. Each profile contains more than 20 folds with a wide range of angles that make it a unique solution for cladding facades on the market.

Characteristics of the cladding profile Cabrera

The Cabrera façade profile is a ribbed metal panel that is applied as an exterior cladding for a ventilated façade, and is manufactured with a lacquered finish in a wide range of metals such as steel, aluminum or zinc. Each Cabrera profile contains more than 20 bends with a wide range of angles that make it a unique façade cladding solution on the market.

It can be placed in both a vertical and horizontal position using a fixing system seen on a steel support substructure.

Manufacturing of the cladding profile Cabrera

The Cabrera profile is manufactured on state-of-the-art automatic folding machines that guarantee the precision of its angles and folds, allowing all the profiles of the same façade to be identical and overlap perfectly.

Additionally, there is the option of manufacturing all the necessary finishes for the façade enclosure from the same coil with which the façade profile was manufactured. This will avoid color differences on the façade and will allow you to receive all the elements necessary for the assembly of the façade at the same time.

Advantages of the cladding profile Cabrera

- Durability: steel, aluminum or zinc are very resistant and durable materials, capable of withstanding the most adverse weather conditions.

- Attractive aesthetics: modern and elegant look. The Cabrera profile is used in different ways, playing with geometry or even in three-dimensional shapes, which allows a wide variety of architectural designs.

- Lightness: despite their resistance, metals such as steel, aluminum or zinc are light materials compared to other coatings, which makes their installation easier and reduces the structural load on the building.

- Reduced Maintenance: metal coatings require minimal maintenance, reducing the need for frequent repairs and repainting.

Technical specifications

Materials:

- DX-51D steel as per UNE-EN 10142

- Aluminium EN 15088

- Galvanized EN 10142

- Galvanized-Precoated EN 10169

- Oven lacquered EN 12206

Dimensions:

| Minimum length | 1,250 mm. |

|---|---|

| Maximum lenght | 6,000 mm. |

| Useful width | 958 mm mm. |

| Thickness | 0.6-0.8 mm. |

- Acero tipo DX51D EN 10142

- Galvanizado EN 10142

- Galvanizado-Prelacado EN 10169

- Aluminio EN 15088

- Lacado al horno EN 12206

Technical documentation

Specifications